Diamonds are among the world’s most precious and desired gemstones. However, they don’t start as the sparkling jewels we see in stores. Instead, they undergo an incredible Transformation journey to reach their full potential.

Once mined, diamonds go through several processes to change from rough, unpolished stones into stunning gemstones that shine with brilliance. This transformation requires advanced cutting technology, skill, and precision, as even a tiny mistake can affect the diamond’s appearance.

In this article, we’ll explore the fascinating process that turns a raw diamond into a dazzling gemstone.

1. Diamond Creation In Mines

Diamonds are mostly made of carbon, one of the most common elements on Earth. Humans and even graphite, which is much softer than diamonds, are also made of carbon. What makes diamonds unique is the way their carbon atoms are bonded. Deep within the Earth’s mantle, carbon atoms are exposed to extreme heat and pressure. This causes them to form a strong, rigid structure where each carbon atom is linked to three others in a tetrahedral shape, creating a diamond.

This rigid structure sometimes allows other elements like nitrogen and boron to attach to the diamond. These elements not only change the diamond’s chemical structure slightly but also affect its color. Over millions of years, geological processes push these diamonds closer to the Earth’s surface, where they can be mined. This incredible journey from deep within the Earth to the surface is what creates the beautiful diamonds we cherish.

2. Diamond Mining

The search for precious gems takes us to diamond mines around the world, where two main methods are used: open-pit mining and alluvial (riverbed or artisanal) mining. Open-pit mining involves digging up large amounts of earth to reach diamond-bearing rocks called kimberlite pipes, while underground mining requires creating tunnels to find diamond-rich ore.

We usually get our rough diamonds from modern open-pit mines. These mines have to follow strict rules to protect the health and safety of workers, the environment, and nearby communities. These rules include plans for mine closure to restore the ecosystem, yearly reports on sustainability, providing benefits to and reducing impacts on local indigenous communities, and regularly checking to minimize environmental and community risks.

Alluvial (artisanal) mining, which is a more traditional and local method, might seem like a more ethical choice, but it has many challenges. It’s hard to ensure that diamonds from these sources aren’t mined by children, that workers are paid fairly, and that mining is done safely for both people and the environment.

Recent events in the diamond industry show the importance of ethical practices. It’s crucial to make sure that the diamonds we value are sourced responsibly, respecting the well-being of workers, local communities, and the environment.

3. Sorting and Grading

Once extracted, the raw diamonds are transported to sorting facilities, where they undergo a meticulous sorting and grading process. This process classifies diamonds based on their size, colour, shape, and clarity. If you want your stone, it could be a previously owned piece of jewellery or diamond, you can contact one of our experts and get to know more about your stone.

4. Cutting and Polishing

The next step in a diamond’s journey is perhaps the most intricate and skilled: cutting and polishing. Master diamond cutters use precision tools to shape the rough diamond into its desired form.

The process involves numerous facets, angles, and proportions to maximize the diamond’s brilliance and sparkle. Each cut is a testament to the cutter’s expertise, and even a minor mistake can greatly affect the diamond’s value.

It involves several other processes that help the diamond truly showcase its characteristics.

Mapping

In the skilled hands of a diamond expert, the rough stone undergoes meticulous mapping.

Laser

A high-powered laser is used to carve away each inclusion ensuring that the stone retains as much of its weight as possible.

Shaping

The craftsmen carefully shape the diamond into an oval cut a classic shape, with its elongated curves, enhances the stone’s inherent beauty.

Blocking

A process where the facets were roughly cut into the stone creating a base upon which the final polish would work its magic.

Final polish

In the skilled hands of a master diamond cutter, the oval diamond received its final, exquisite polish until it gleamed with a radiant, mirror-like finish.

Once the diamond has been cut and polished, it undergoes a final inspection to ensure that it meets the strict standards of quality and beauty that are expected of a diamond.

5. Certification

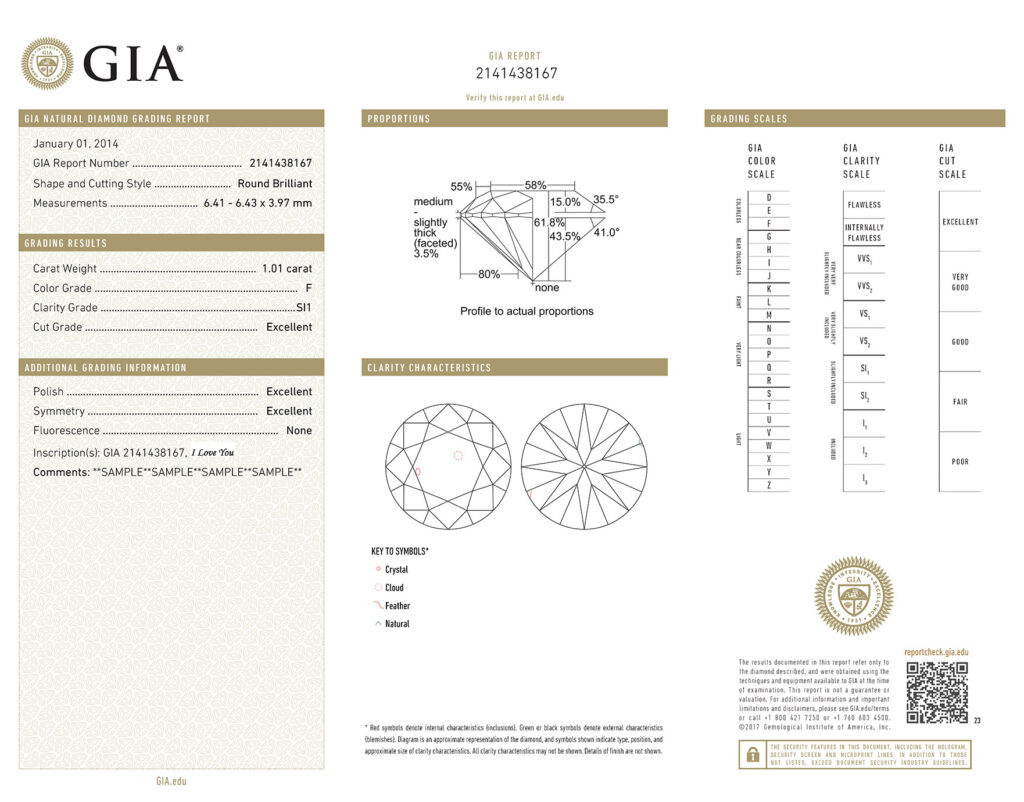

After cutting and polishing, the diamond undergoes a thorough evaluation by gemologists to assess its quality and characteristics. It is then accompanied by a certificate, which serves as its unique identity card. This certificate provides detailed information about the diamond’s carat weight, colour, clarity, and cut.

6. Jewellery Design and Setting

Once certified, diamonds find their way into the hands of jewellery designers and artisans. These skilled craftsmen create stunning pieces of jewellery, such as engagement rings, necklaces, and earrings, that showcase the diamond’s beauty. The design and setting process involves selecting complementary metals and gemstones to enhance the diamond’s appeal.

7. Retail and Customer Acquisition

The journey of a diamond is completed when it arrives at a jewellery store or diamond dealer, where it can be showcased to potential customers. Customers interested in purchasing a diamond have the opportunity to explore a wide range of options, from solitaire engagement rings to intricate diamond-studded jewellery.