Introduction

Diamonds are renowned for their beauty and value, but achieving the perfect diamond involves a meticulous manufacturing process with rigorous quality control measures. From the initial rough stone to the final polished gem, each stage requires careful monitoring to ensure the highest standards of quality. This blog delves into the quality control processes in diamond manufacturing that ensure every diamond meets the exacting criteria of excellence.

The Importance of Quality Control

Quality control is vital in diamond manufacturing for several reasons:

- Consistency: Ensures that every diamond meets the specified quality standards.

- Value Maximization: Maintains the diamond’s value by ensuring its clarity, cut, color, and carat weight are optimal.

- Consumer Trust: Builds confidence in the brand and product, ensuring consumer satisfaction and loyalty.

- Compliance: Meets industry standards and regulatory requirements, avoiding legal and reputational risks.

Key Stages of Quality Control in Diamond Manufacturing

1. Initial Assessment and Sorting

Before a rough diamond is processed, it undergoes an initial assessment:

- Visual Inspection: Experts visually inspect the rough stone to evaluate its potential and identify any visible flaws.

- Sorting: Stones are sorted based on size, shape, and quality. Advanced technology such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) can assist in this process.

2. Planning and Mapping

Precision planning is crucial for maximizing the diamond’s yield:

- 3D Mapping: Advanced software creates a 3D model of the rough diamond, revealing internal features and inclusions.

- Cutting Plan: The best possible cutting plan is devised to maximize carat weight and minimize waste, while ensuring optimal clarity and brilliance.

3. Cutting and Bruting

The cutting stage involves the transformation of the rough diamond into a polished gem:

- Laser Cutting: High-precision lasers cut the diamond according to the pre-determined plan. Quality control ensures cuts are accurate and follow the mapped lines.

- Bruting: The diamond is shaped into a round outline. Automated machines and skilled craftsmen ensure the shape is symmetrical and meets specified dimensions.

4. Polishing

Polishing is critical to achieving the diamond’s final appearance:

- Facet Creation: Polishing creates the diamond’s facets, enhancing its brilliance and fire. Each facet must be perfectly aligned and polished.

- Symmetry and Proportion Checks: Quality control ensures each facet is symmetrical and the diamond’s proportions adhere to ideal standards.

5. Inspection and Grading

After the diamond is cut and polished, it undergoes rigorous inspection:

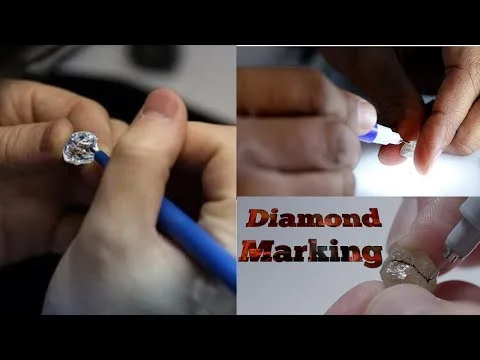

- Internal and External Examination: Using microscopes and other tools, experts check for inclusions, blemishes, and overall clarity.

- Certification: The diamond is graded based on the 4 Cs (Cut, Clarity, Color, Carat) by recognized gemological laboratories such as GIA, AGS, or HRD. A certificate is issued, detailing the diamond’s characteristics.

Technologies in Diamond Quality Control

Modern technology plays a crucial role in ensuring diamond quality:

- Laser Scanning and Imaging: Provides detailed views of the diamond’s internal structure, ensuring precise cutting and polishing.

- Automated Grading Systems: Machines equipped with artificial intelligence (AI) offer consistent and unbiased grading.

- Spectrophotometers: Measure the diamond’s color with high accuracy, ensuring consistency across batches.

Challenges in Quality Control

Despite advancements, quality control in diamond manufacturing faces several challenges:

- Subjectivity in Grading: Human graders may have slight variations in grading, though automated systems help mitigate this.

- Inclusion Management: Ensuring that inclusions are minimized or placed in less visible areas requires high skill and precision.

- Maintaining Standards: Adhering to stringent industry standards and consumer expectations demands continuous monitoring and improvement.

Conclusion

Quality control in diamond manufacturing is a complex but essential process that ensures each diamond meets the highest standards of excellence. Through meticulous inspection, advanced technology, and adherence to stringent standards, manufacturers can deliver diamonds that are not only beautiful and valuable but also trusted by consumers worldwide. By understanding and implementing robust quality control measures, the diamond industry continues to uphold its legacy of brilliance and perfection.