Introduction

Diamond bruting is a critical step in the diamond manufacturing process, where the rough diamond is shaped into a round outline. This stage ensures that the diamond achieves the desired proportions and symmetry, essential for maximizing its brilliance and value. With advancements in technology, diamond bruting has evolved significantly, enhancing precision, efficiency, and the overall quality of the finished gemstone. In this blog, we explore the latest technologies revolutionizing diamond bruting.

The Evolution of Diamond Bruting

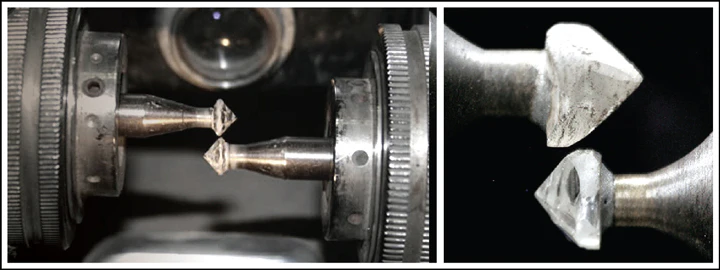

Traditionally, diamond bruting was done manually, with diamond cutters using another diamond to grind the rough stone into shape. This method, though effective, required a high level of skill and experience, and was time-consuming. However, with technological advancements, the industry has seen a shift towards more automated and precise bruting techniques.

Latest Technologies in Diamond Bruting

1. Laser Bruting

Laser technology has brought a significant transformation to diamond bruting. Lasers allow for precise control over the cutting process, minimizing human error and reducing material wastage. The main advantages of laser bruting include:

- Precision: Lasers can create extremely accurate cuts, ensuring perfect symmetry and roundness.

- Speed: The process is much faster compared to traditional methods.

- Safety: Reduces the risk of damaging the diamond, as the laser can be controlled with high accuracy.

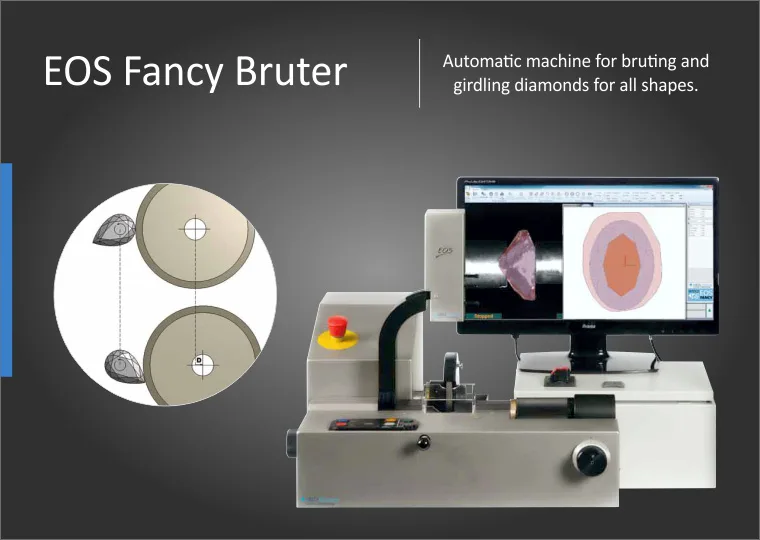

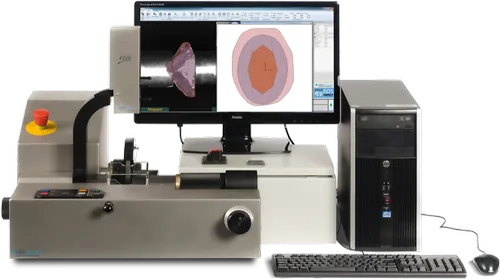

2. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

The integration of CAD and CAM systems has revolutionized diamond bruting. These technologies allow for detailed planning and execution of the bruting process. Key benefits include:

- Customization: CAD software can design unique and precise shapes for each diamond based on its individual characteristics.

- Simulation: CAM systems can simulate the bruting process before it is executed, identifying potential issues and optimizing the procedure.

- Efficiency: Automated CAM machines can perform bruting with minimal human intervention, increasing productivity and consistency.

3. Robotic Bruting Machines

Robotic bruting machines represent the pinnacle of automation in diamond cutting. These machines are equipped with advanced sensors and artificial intelligence to perform bruting with unprecedented precision. Features include:

- AI Integration: Uses AI to adapt to the diamond’s unique structure, ensuring optimal cuts.

- High Precision: Robots can make micro-adjustments during the bruting process, enhancing accuracy.

- Consistency: Delivers uniform results across multiple stones, ensuring high-quality output.

4. Ultrasonic Bruting

Ultrasonic technology is another innovative approach in diamond bruting. It involves using high-frequency sound waves to shape the diamond. The benefits of ultrasonic bruting include:

- Gentle Process: Reduces the risk of micro-fractures, preserving the diamond’s integrity.

- Precision: Offers fine control over the bruting process, ensuring precise shaping.

- Efficiency: Can be faster and more efficient for certain types of rough diamonds.

The Future of Diamond Bruting

As technology continues to advance, the future of diamond bruting looks promising. Upcoming innovations might include:

- Enhanced AI and Machine Learning: Further integration of AI could allow machines to learn from each bruting process, continually improving accuracy and efficiency.

- Augmented Reality (AR): AR could assist diamond cutters in visualizing the bruting process in real-time, offering guidance and reducing errors.

- Sustainable Practices: Technology will continue to evolve to ensure that bruting processes are more environmentally friendly, reducing energy consumption and material waste.

Conclusion

The latest technologies in diamond bruting are transforming the industry, providing tools that enhance precision, efficiency, and safety. From laser bruting to AI-powered robotic machines, these advancements ensure that each diamond is shaped to perfection, maximizing its brilliance and value. As the industry continues to innovate, we can expect even more exciting developments in the field of diamond bruting, making the process faster, safer, and more efficient than ever before.